What is Electroplating? Definition, Working Principle, and Uses

In this blog, we are going to learn what is electroplating, its uses, and its working principle. Electroplating is done to prevent the corrosion of metals and also for decorative purposes. It is done to enhance the surface features and thickness of an object.

Uses Of Electroplating

Recall that a brand new bicycle has shiny handlebar and wheel rims. However, if these are accidentally scratched, the shiny coating comes off revealing a not-so-shiny surface beneath.

You might have also seen women using ornaments, which appear to be made of gold. However, with repeated use, the gold coating wears off, revealing silver or some other metal beneath. In both these cases, metal has a coating of another metal.

Do you wonder how a layer of one metal can be deposited on top of another? Well, let us try doing it ourselves. When an electric current is passed through the copper sulfate solution, copper sulfate dissociates into copper and sulfate.

The free copper gets drawn to the electrode connected to the negative terminal of the battery and gets deposited on it. But what about the loss of copper from the solution?

From the other electrode, a copper plate, an equal amount of copper gets dissolved in the solution. Thus, the loss of copper from the solution is restored and the process keeps going. This means that copper gets transferred from one electrode to the other.

Define electroplating

The process of depositing a layer of any desired metal on another material by means of electricity is called electroplating. It is one of the most common applications of the chemical effects of electric current.

Uses of Electroplating

- Electroplating is a very useful process. It is widely used in industry for coating metal objects with a thin layer of a different metal.

- The layer of metal deposited has some desired property, which the metal of the object lacks. For example, chromium plating is done on many objects such as car parts, bath taps, kitchen gas burners, bicycle handlebars, wheel rims, and many others.

- Chromium has a shiny appearance. It does not corrode. It resists scratches. However, chromium is expensive and it may not be economical to make the whole object out of chromium. So the object is made from a cheaper metal and only a coating of chromium over it is deposited. Jewelry makers electroplate

- Silver and gold on less expensive metals. These ornaments have the appearance of silver or gold but are much less expensive.

- Tin cans, used for storing food, are made by electroplating tin onto the iron. Tin is less reactive than iron. Thus, food does not come into contact with iron and is protected from getting spoilt.

- Iron is used in bridges and automobiles to provide strength. However, iron tends to corrode and rust. So, a coating of zinc is deposited on iron to protect it from corrosion and the formation of rust.

- Electroplating reduces friction.

- The thickness of a metal surface is increased after the process of electroplating.

- Electrical conductivity is enhanced with the help of electroplating.

Read More- Magnetic Field and Magnetic Field Lines | Maxwell�s Corkscrew Rule

FAQs

Related post:

- Types of Chemical Reactions With Examples - Class 10 - Studynlearn

- How to Write Chemical Equations? Writing Chemical Formulae - Examples

- Better Housekeeping Practices To Avoid Wastewater: Class 7 - Studynlearn

- What is Sewage: Types Of Sewage and Sewage Disposal - Class 7

- Wastewater Treatment Plant: Anaerobic Decomposition and Cleaning of Water

- What Are Cell Organelles: Types and Their Functions - Studynlearn

- Sheep Rearing: Advantages - Sheep Rearing in Australia - Case Study

- Sheep Shearing: Explanation, Procedure, and Precautions - Class 7

- Hydropower: Explanation and Advantages of Hydroelectric Power

- Sowing Methods: Broadcasting, Dibbling, Drilling and Others - Class 7

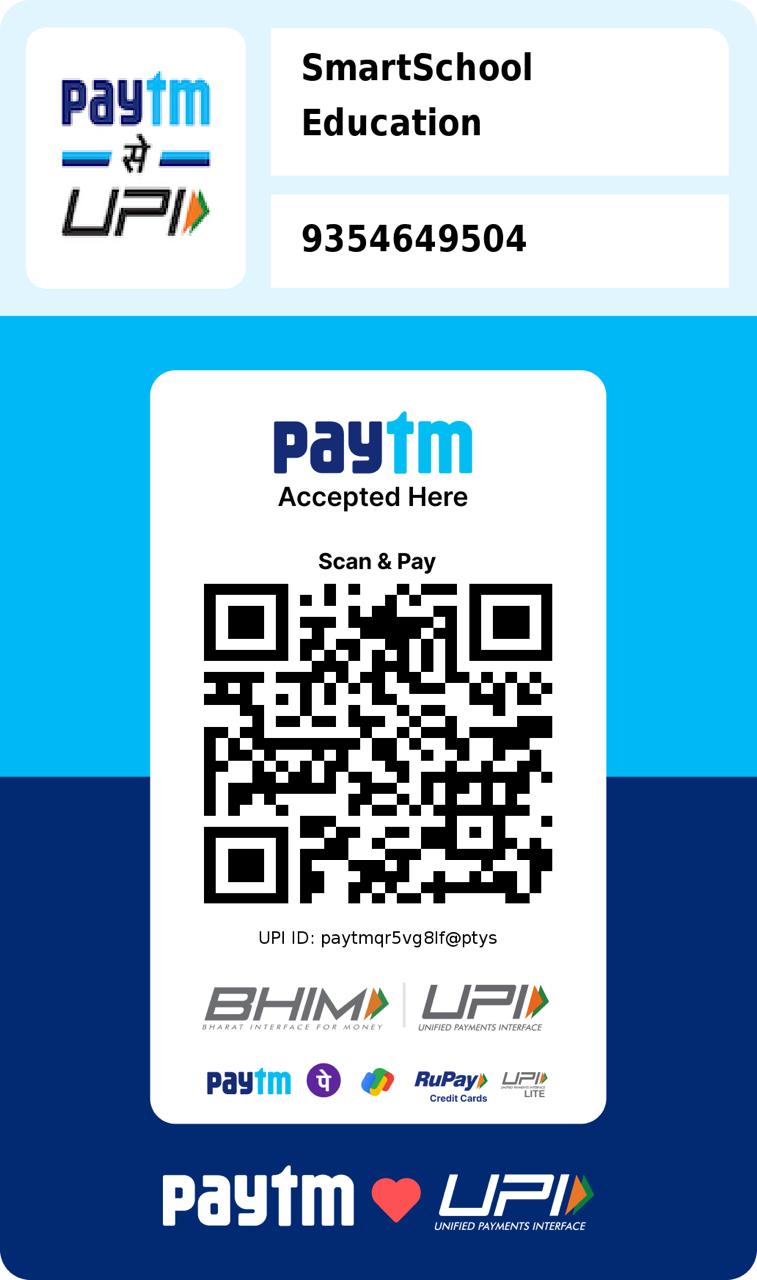

Payment

Payment